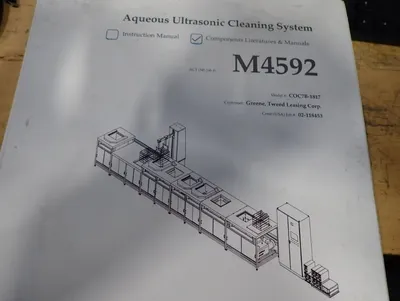

Originally manufactured in 2014, Tested at factory only, never in operation

6-Tank with tank: 18”x17”x18” D - great for PASSIVATION

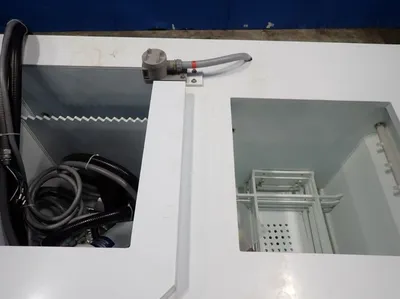

Currently, this unit is set up with 40 KhZ ultrasonic transducers mounted to the base of the

3-Polyethylene tanks, Air-Blow (with cables, NO generators), blow dryer PLUS Vacuum Dry

Currently, buyer can operated this unit manually or upgrade to Fully Automatic transfer system.

We are offering this unit up and running for manual operation, "As-Is" or with assistance in upgrading

to a fully automated transfer system

I any of these options we offer you all the documentation gathered, contacts at crest and supoort prior to moving. Original buuld, 2014. Tested at Crest Ultrasonic and never installed

Originally manufactured in 2014, Factory tested and has never been installed.

Designed with Nylon (polypropylene) tanks over stainless steel transducers tank.

Ultrasonic 6-tank / 8-station system; and, can be made fully automated with some upgrades.

the Rigibot Robot is include and buyer would need to puchase additional standard track extension from Crest Ultrasonic.

The design of this unit was originally for Wash, Rinse, Passivate, Rinse and Blow Dry - Vacuum Dry

System includes a final vacuum drying tank to speed up the drying process.

Tank size 18”x17”x18” deep and 18" x 17" x 15" if buyer wishes to introduce emmersible ultrasonics.

The unit can be configured as a 5 or 6 tanks System, depending if buyer removes one of the dryer.

Excellent for passivation

Crest Rigibot CTS-2000-AB-MAPLE Robot installed. Track is complete through 2-stations. Additional track can be ordered through Crest Ultrasonics to use all 8 stations (please inquire).

Controller: A-B CLC-500 PLC

====================================================================================

PLEASE INQUIRE ABOUT OUR MAKING THIS UNIT FULLY AUTOMATED, TO ORIGINAL SPECIFICATION

====================================================================================

To the best of our knowledge all details listed below are deemed correct.

It is the buyer’s responsibility to confirm all details and we encourage an inspection of the machine(s) and accessories prior to purchase.

Stations:

1: Load platform station

2: Ultrasonic immersion wash

3: Spray rinse to drain

4: Ultrasonicacid wash (Citric Passivation)

5: Ultrasonic Rinse

6: Recirculation hot air dryer

7: Vacuum dryer console (CVDs‐1817) (this second dryer will decrease total drying

time by 35% (approx)

8: Off-Load basket positioner platform

General Specifications:

Tank Dimensions: 18″ X 17″ X 18″ (126)″ (current set up with transducers mounted to

underside of tank [left to right X front to back X depth (liquid depth)]

Process Flow: Left to Right

Automation: CTS‐2000‐AB‐MAPLE‐RIGIBOT

Power Requirement:

System: 480Volts/60Hz/3 phase/70.6Amp

Quick Dump: 480Volts/60Hz/3 phase

Fire Suppression: 480Volts/60Hz/3 phase/46.3Amp

Frame Material: Type 304 stainless steel, lift‐out access panels on the side and rear.

Access Panels: Type 304, #4 finish, stainless steel sliding access door on the front.

Countertop: A type 304polypropylene, removable countertop. The countertop will be fitted with removable polypropylene drainbacks (between the process stations).

Base Plate: A type 304 stainless steel base plate.

Rigibot CTS-2000-AB-MAPLE

Control: Allen-Bradley SLC500 PLC

(Maple system 1550H color touch screen

Capacity: 200 lbs

Travel Speed (Horizontal/Vertical): 100 / 17 FPM

Positioning Accuracy (Horizontal/Vertical): 0.2" / +/- 0.02"

Dimensions:

Machine (LxD) with Robot: 273” x 60”

Machine (LxD) without Robot: 273” x 50”

Machine (LxD) w/o Robot AND Track (Using manually): 273” x 40”

Control Cabinet: 33” x 21” (plenty of cable for locating control)

**** Note: Today, this unit quotes new for over $325,000 and 48-68 week ETA

--------------------------------------------------------------------------------------

We use cookies to improve your experience. Privacy Policy.