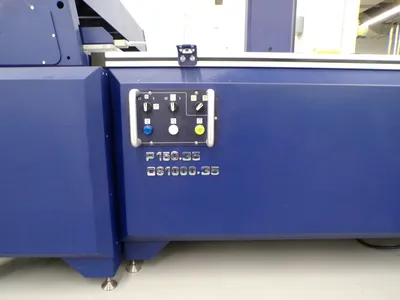

INSPECVISION PLANAR 150.35 OPTICAL QC SCANNER WITH OPTI-SCAN 1000.35LA, NEW: 2021

PALNAR 150.35:

MAX. COMPONENT LENGTH: 59”

MAX. COMPONENT WIDTH: 39.37”

MAX. COMPONENT THICKNESS: 13.78”

MAX. COMPONENT WEIGHT: 551 LBS – UDL (UNIFORMLY DISTRIBUTED LOAD)

MEASURING ACCURACY:

- LENGTH: (+/-) 1.378”

- WIDTH: 2.75”

MEASURING ACCURACY HEIGHT (OPTIONAL): (+/-) 3.9”

MEASURING SPEED: 0.0098” PS

CAMERA: INDUSTRIALISED ULTRA HIGH RESOLUTION PROFESSIONALLY MOUNTED IN SEALED

_ ENCLOSURE

DOT LASER HEIGHT MEASURING DEVICE (OPTIONAL): CLASS III R PRECISION LASER

COMPUTER PROCESSOR: INTEL QUAD OR DUAL CORE

PROCESSOR SPEED: 3GHZ

HARD DISK: 125GB

SCREEN: 20 INCH FLAT SCREEN OR BETTER

PERIPHERAL EQUIPMENT: KEYBOARD AND OPTICAL MOUSE

OPERATING SOFTWARE: WINDOWS 10 - 64 BIT

PROPRIETARY INSPECVISION SOFTWARE: INSPECTION, SPC, REPORTING, REVERSE ENGINEERING

DATA CABLE: USB 2 OR USB 3

KVM: KEYBOARD, VIDEO DISPLAY & MOUSE STAND (PC INTEGRATED INTO LIGHT TABLE ASSEMBLY)

LIGHT TABLE CONSTRUCTION: FRAME WITH REMOVABLE SHEET METAL CLADDING

LIGHT TABLE MEASURING SURFACE: LAMINATE GLASS, TOUGHENED WITH INTEGRAL DIFFUSION

- LAYER

LIGHT SOURCE: HIGH EFFICIENCY LEDS

MAST CONSTRUCTION: HEAVY FOLDED SHEET METAL CONSTRUCTION

POWER SUPPLY: 230 VOLT, SINGLE PHASE, 50HZ OR 110 VOLT, SINGLE PHASE, 60HZ ON REQUEST

POWER CONSUMPTION: 4 AMP MAXIMUM AT 230 VOLT, 8 AMP MAX AT 110 VOLT

PROTECTIVE DEVICES: CIRCUIT BREAKERS, MOUNTED AT REAR OF LIGHT TABLE

CONTROL PANEL: CONTROL SWITCHES FOR POWER, CAMERA AND LIGHTS, MAIN POWER INDICATOR

EC DIRECTIVES: COMPLIANT WITH MACHINERY, LOW VOLTAGE AND EMC DIRECTIVES

AMBIENT OPERATING CONDITIONS: 10-30 DEGREE C

APPROX. FOOTPRIN TOF INSTALLED lIGHT TABLE AND MAST: 73.7”(W) x 56.6”(D) x 144.7”(H)

APPROX. WEIGHT OF LIGHT TABLE AND MAST: 1,819 LBS

APPROX. FOOTPRINT OF INSTALLED WICOMPUTER CABINET: 28”(W) x 18.6” (D) x 68.5”(H)

APPROX. WEIGHT OF INSTALLED WICOMPUTER CABINET: 100 LBS

OPTI-SCAN 1000.35:

MAX. SINGLE SCAN AREA:

- X-AXIS: 39.37

- Y-AXIS 24.6”

MAX. SINGLE SCAN DEPTH Z-AXIS: 24.6”

VOLUMETRIC ACCURACY: 75 MICRONS

REPEATABILITY: 35 MICRONS

POINT SPACING: BETTER THAN 210 MICRONS

SCANNING SPEED: 250,000 POINTS PS

SCANNING TIME: 10 SEC.

PROCESSING TIME: 5 SEC.

PERIPHERAL EQUIPMENT: USB LIGHTING CONTROLLER, STANDARD COMPUTER - INTERFACE

REQUIRED OPERATING SYSTEM: WINDOWS 10

CAMERA: 18 MEGA-PIXELS

PROJECTION SOURCE: LED/LASER PROJECTOR

DATA CABLES : HDMI AND USB3

POWER SUPPLY: 110-240V 50/60HZ

POWER CONSUMPTION: 1.5 AMP MAX. AT 230 VOLT, 3 AMP MAX. AT 110 VOLT

EC DIRECTIVES: COMPLIANT WITH MACHINERY, LOW VOLTAGE AND EMC DIRECTIVES

AMBIENT OPERATING CONDITIONS: 5-35 DEGREE C

APPROX. FOOTPRINT: 47.8”(W) x 33.6”(D) x 58.7”(H)

APPROX. WEIGHT: 56 LBS (TRIPOD)

* SOFTWARE INCLUDE: 3D SCANNING, AUTOMATED REPOSITIONING, TEXTURE MAP ACQUISITION,

3D COLOR RENDERING, CREATION OF CROSS-SECTIONS, CREATION OF 3D EDGES,

REVERSE ENGINEERING OF 3D EDGES TO DXF/DWG, COMPARISON OF 3D EDGES TO DXF/DWG,

REVERSE PROJECTION OF COLORED DEVIATION REPORTS ONTO PART, CREATION OF 3D POINT

CLOUDS IN PLY, STL, VRML, ASCII FORMATS, CREATION OF TEXTURE MAPPED POINT CLOUDS,

CALIBRATION SOFTWARE.

* FREE 3D INSPECTION SOFTWARE: FULLY COMPATIBLE WITH OFF THE SHELF FREE 3D INSPECTION

SOFTWARE. FUNCTIONALITY INCLUDES COMPARISON TO 3D SOLID MODELS, DIMENSIONING, GD&T,

CROSS-SECTIONS, FULL SURFACE DEVIATION INSPECTION, MERGING OF SCANS, CUSTOMIZABLE

REPORTS, AUTOMATIC ALIGNMENT OF SCAN TO CAD, POINT CLOUD MESHING, PROCESSING AND

FILTERING, EXTRACTION OF NOMINAL DATA FROM CAD MODEL, COMPARISON OF 2 SCANS.

* ADVANCED 3D INSPECTION SOFTWARE OPTION (GEOMAGIC CONTROL): AVAILABLE ON REQUEST. COMPARISON TO 3D SOLID MODELS, GD&T, SPC, CROSS-SECTIONS, FULL SURFACE AND EDGE INSPECTION, CREATION OF REPORT TEMPLATES, AUTOMATED MERGING OF POINT CLOUDS, AUTOMATIC ALIGNMENT OF SCAN TO CAD, AUTOMATIC POINT CLOUD PROCESSING AND FILTERING, AUTOMATIC DETECTION OR REPOSITIONING SPHERES, MACRO CREATION FOR FULL AUTOMATION, AUTOMATIC EXTRACTION OF NOMINAL DATA FROM CAD MODEL, COMPARISON OF 2 SCANS.

* 3D REVERSE ENGINEERING (ADVANCED PACKAGE): AVAILABLE ON REQUEST. CREATION OF 3D

SOLID MODELS FROM SCAN DATA.

* CALIBRATION KIT INCLUDED: RETRO-REFLECTIVE REFERENCE MARKERS MOUNTED ONTO STEEL

PLATE WITH REPOSITIONING FRAME

* ACCURACY VERIFICATION OBJECT : CALIBRATED BALL BAR * OPTISCAN CONSTRUCTION: CAMERA AND PROJECTOR ASSEMBLIES MOUNTED ON FLOATING CARBON FIBRE CHASSIS

* OPTISCAN ENCLOSURE : ABS CARBON FIBRE EFFECT

* REPOSITIONING MARKERS: SET OF 24 LOOSE MAGNETIC PHOTOGRAMMETRIC MARKERS TO ALLOW

REPOSITIONING

We use cookies to improve your experience. Privacy Policy.