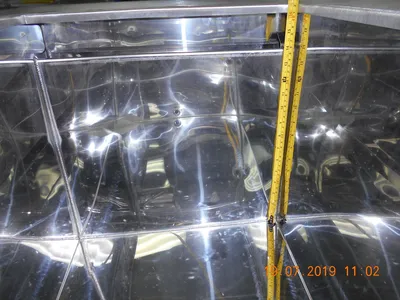

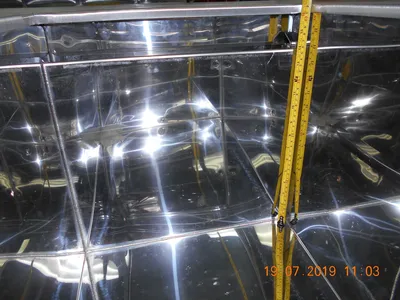

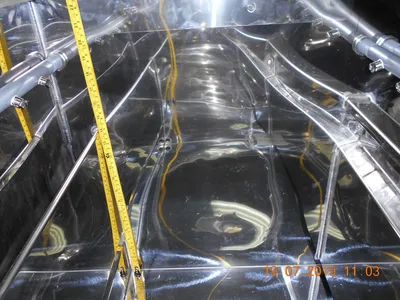

Crest Ultrasonics OC5-1622-HE 5-station Ultrasonic Cleaning System (new in 2019, approx)

Specifications from OEM brochure and equipped with are described to the best

of our knowledge. ALL items should be confirmed by buyer.

Super Clean and Extremely Well Maintained!

OC5-1622-HE – Five Stations Optimum Console

Tank Dimensions: 16" left to right by 22" front to back by 16" deep (14" liquid depth).

Overall Dimension: 132" left to right x 43" front to back x 44" high

Process: Wash, Wash, Rinse, Rinse, Dry.

Chemistry: Deionized Water

NOT MANUFACTURED FOR USE WITH ANY FLAMMABLE LIQUIDS

Facilities:

2-3 GPM (7-8 GPM on demand) DIW@ 1-2 Mohm-cm, 30-35 psi and process temperature,

90-95 CFM CDA @ 30 psi, 1-2 CFM shop air @ 60psi, unrestricted floor drain.

Power Requirements: 240 volts/60 Hz/3 phase

Work Flow: Left to Right

System Detail:

Tank Material: Type 316L stainless steel with a Bright Annealed finish.

Frame Material: Type 304 stainless steel support frame with leveling legs.

Access Panel: - Type 304 stainless steel, lift-out access panels on the sides and rear.

-Type 304, #4 finish, stainless steel sliding access doors on the front.

Countertop: A type 304 stainless steel, removable, countertop. The countertop will be fitted with a 304 stainless steel,

removable drainbacks (between the process stations)

Base Plate: A type 304 stainless steel base plate.

Plumbing: Complete hard plumbed process piping:

- Individual fill and drain connections (at the rear utility panel) will be provided for each of the wash station.

- Common fill and drain connections (at the rear utility panel) will be provided for the cascade rinse stations.

- All appropriate flow control and isolation ball valves.

Electrical Box: Single-point electrical connection located in an end mounted NEMA 12 enclosure.

Basket: Model B-1622 stainless steel work basket. Fabricated from type 304 stainless steel. Mesh size: ¼‛ (other mesh

sizes available). Design to hold 50 lbs of parts.

System:

Station #1: Ultrasonic Immersion Wash

Maximum Temperature: 160 °F

Ultrasonic Frequency: 40 kHz

Ultrasonic Power: 1000 watts of ultrasonic power provided by:

• Twelve (12) transducer modules direct-bonded to the bottom of the tank

• One (1) Model CG-1000-40-T ultrasonic generator

• Heat: 4000 watts of strip heat

Temperature control: Digital indicating temperature controller with a RTD type temperature probe.

Filtration: A 10 GPM recirculation/filtration system with:

• One (1) wye strainer

• One (1) centrifugal, mag-drive pump, with:

o Ryton head.

o Viton o-ring

o TEFC motor

• One (1) 10", 10 micron cartridge filter housed in a stainless steel canister

•One (1) analog pressure gauge

• Manual flow control valves.

• One (1) recirculation returns surface sparger.

Standard Features: An electronic ultrasonic cycle timer

•A float-type low liquid level safety

• A capillary bulb-type overtemperature safety

thermostat.

•A basket positioner

• A stainless steel lift-off cover.

• A rear overflow weir plumbed to the recirculation

system.

Plumbing:

• Stainless steel compression fittings up to 1‛ OD

• Stainless steel threaded pipe ¾‛ to 1-½‛wherever

necessary.

Station #2: Ultrasonic Immersion Wash

Maximum Temperature: 160°F

Ultrasonic Frequency: 40kHz

Ultrasonic Power: 1000 watts of ultrasonic power provided by:

• Twelve (12) transducer modules direct-bonded to the

bottom of the tank.

• One (1) Model CG-1000-40-T ultrasonic generators.

Heat: 4000 watts of strip heat

Temperature control: Digital indicating temperature controller with a RTD type temperature probe.

Filtration: A 10 GPM recirculation/filtration system with:

• One (1) wye strainer

• One (1) centrifugal, mag drive pump, with.

o Ryton head

o Viton o-ring

o TEFC motor

•One (1) 10‛, 10 micron cartridge filter housed in a

stainless steel canister.

•One (1) analog pressure gauge.

•Manual flow control valves.

•One (1) recirculation returns surface sparger.

Standard: features

• An electronic ultrasonic cycle timer

• A float-type low liquid level safety

• A capillary bulb-type overtemperature safety thermostat.

• A basket positioner

•A stainless steel lift off cover.

• A rear overflow weir plumbed to the recirculation system.

Plumbing:

•Stainless steel compression fittings up to 1‛ OD.

• Stainless steel threaded pipe ¾‛ to 1½‛ wherever

necessary.

Station #3: Ultrasonic Spray-Over-Immersion Rinse

Maximum Temperature: 120 °F

Ultrasonic Frequency: 132 kHz

Ultrasonic Power: 1000 watts of ultrasonic power provided by:

• Twenty Four (24) transducer modules direct-bonded to the bottom of the

tank

• Two (2) Model MW500 HMI/132A (part # 72258003) ultrasonic generators.

Heat: 4000 watts of strip heat

Temperature control: PLC controls process temperature with a RTD-type temperature probe.

Temperature control: Digital indicating temperature controller with a RTD type temperature probe.

Spray rinse: Stationary spray rinse package, with:

•One (1) set of parallel-opposed spray rinse headers that

are:

o Fitted with removable nozzles

o Located near the top of the tank

•A solenoid valve on the incoming water line

o The solenoid is controlled via a footswitch

Standard features:

• An electronic ultrasonic cycle timer.

•A capillary bulb-type overtemperature safety

thermostat.

• A basket positioner

•A stainless steel lift-off cover.

•A side-located overflow weir plumbed to drain.

Plumbing: CPVP pipe and fitting for incoming and drain

Station #4: Ultrasonic Spray-Over-Immersion Rinse

Maximum Temperature: 120 °F

Ultrasonic Frequency: 132 kHz

Ultrasonic Power: 1000 watts of ultrasonic power provided by:

• Twenty Four (24) transducer modules direct-bonded to the bottom of the

tank

• Two (2) Model MW500 HMI/132A (part # 72258003) ultrasonic generators.

Heat: 4000 watts of strip heat.

Temperature Control: Digital indicating temperature controller with a RTD type temperature probe.

Spray Rinse: Stationary spray rinse package, with:

• One (1) set of parallel opposed spray rinse headers that

are:

o Fitted with removable nozzles.

o Located near the top of the tank.

• A solenoid valve on the incoming water line.

o The solenoid is controlled via a footswitch.

Standard Features:

• An electronic ultrasonic cycle timer.

•A capillary bulb type overtemperature safety

thermostat.

• A basket positioner.

• A stainless steel lift off cover.

• A side located overflow baffle with cascade flow to Station #3.

Plumbing: CPVC pipe and fitting for incoming and drain.

Station #5: Recirculating Hot Air Dry

Maximum Temperature: 180 °F

Heat 10000 watts of heat

Temperature control: Digital indicating temperature controller with a RTD type temperature probe.

Blower: An 1100 CFM recirculating blower in the updraft orientation.

Blow-off: A stationary blow off package, with :

•One (1) set of parallel-opposed air blow-off headers

that are :

o Located near the top of the tank

•A solenoid valve on the incoming air line

o The solenoid is controlled via a push button.

Cover A manual sliding cover.

Plumbing: Stainless steel tubing and fittings and brass valves.

HEPA filter: 0.3 HEPA Filter including a differential pressure gauge.

Product Information:

1. Standard power requirement;

208/240/480 volts, 3 phase optional (transformer required for 480V)

380/415 volts, 3 phase optional (transformer required for 480V)

2. Dimension do not include load/unload tables for automation or 15‛

(38mm) external generator rack.

3. Ultrasonic Frequency ranges from 25kHz, 40kHz, 58kHz, 68kHz,

132kHz & 192 kHz.

SHIPPING DIMENSIONS:

Approx.132" left to right x 43" front to back x 44" high

We use cookies to improve your experience. Privacy Policy.